A Comprehensive Guide to Injection Moulding: All You Need to Know

From everyday household items to complex car parts, injection moulding has revolutionized the manufacturing sector. This versatile process allows for the mass production of parts with intricate designs and consistent quality. If you're considering injection moulding for your next project or are just curious about its ins and outs, this article is for you.

What is Injection Moulding?

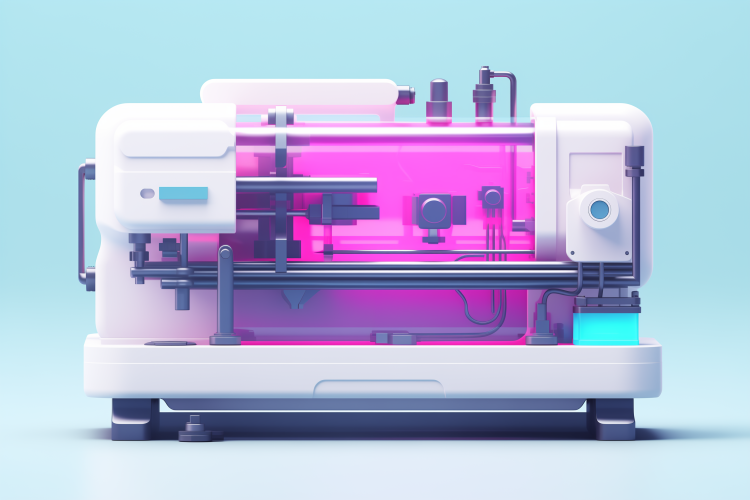

Injection moulding begins with an injection moulding machine, a sophisticated piece of equipment designed to handle various materials, primarily plastics and rubbers. The core of this process lies in the precision and efficiency of the machine, which heats the material until it reaches a fluid state and then injects it into a mould. This mould, often custom-designed for specific parts, shapes the molten material into the desired form.

Injection moulding, a cornerstone in the world of modern manufacturing, has a rich history dating back to the late 19th century. It began in 1872 with the invention of the first injection moulding machine by John Wesley Hyatt, a device initially designed to produce billiard balls from celluloid. This innovation marked the birth of a new era in mass production, enabling the efficient creation of complex shapes. Over the decades, this process evolved significantly with advancements in materials, machinery, and computer-aided design. The introduction of thermoplastics in the 1940s revolutionized the industry, offering greater flexibility and durability in products. Today, in the modern world, injection moulding has been transformed by digital technology and automation. The integration of 3D CAD software, computer-controlled machinery, and advanced robotics has not only increased precision and efficiency but also expanded the possibilities of design and scale. This technological evolution has made injection moulding an indispensable tool in diverse industries, from medical devices to automotive manufacturing, shaping the very fabric of our daily lives.

Injection Moulding Machines: The Heart of the Process

Injection moulding machines are the backbone of the injection moulding process, pivotal in transforming raw materials into finished products. These machines, whether designed for plastic or rubber, play a critical role in heating the material to a pliable state and then injecting it into a mould under high pressure. This process requires precision and control, characteristics that are central to the functionality of these machines. They come in a variety of types and sizes, tailored to different production needs. Smaller machines are typically used for producing precision parts where detail and accuracy are paramount, making them ideal for electronics, medical devices, and other small-scale applications. On the other end of the spectrum, large-scale injection moulding machines are used in industries like automotive and construction, where they produce larger components. These machines are capable of handling high volumes and more substantial materials, demonstrating the versatility of the injection moulding process.

For those who are cost-conscious, such as small businesses or hobbyists, there are budget-friendly options available. Used injection moulding machines, which have been refurbished or are simply pre-owned, provide a more affordable entry point into the world of moulding. These machines can offer the same functionality as newer models but at a fraction of the cost. Additionally, businesses often have the option to purchase injection moulding machines that are on sale, further reducing the financial barrier to this technology. Regardless of the scale or budget, there is an injection moulding machine suitable for every need, ensuring that this technology remains accessible and adaptable.

Designing for Injection Moulding

Injection moulding design is a crucial phase. To maximize the process, designing for injection moulding is imperative. Proper design ensures that the mould fills properly, the parts eject smoothly, and production remains consistent. Advanced 3D CAD tools can be especially helpful during this phase, enabling designers to visualize and rectify potential issues before production begins.

Here are some key considerations for 3D CAD in injection moulding:

Material Selection: Different materials behave differently under the injection moulding process. Using 3D CAD, designers can simulate how various materials will react, considering factors like shrinkage, warping, and cooling time.

Wall Thickness: Uniform wall thickness is crucial for injection moulding. Inconsistent thickness can lead to problems like warping or sink marks. 3D CAD software helps in maintaining consistent wall thickness throughout the design.

Draft Angles: Slight angles on the walls of the part, known as draft angles, are essential for easy ejection from the mould. 3D CAD allows for precise calculation and application of these angles.

Gates and Runners: The gate is where the molten material enters the mould, and runners are channels within the mould that guide the material to different parts. 3D CAD aids in optimally placing gates and runners to ensure even flow and reduce material wastage.

Ribs and Bosses: Ribs are used to strengthen thin-walled parts, and bosses provide points for fasteners like screws. 3D CAD assists in designing these features in a way that doesn't compromise the overall integrity of the part.

Cooling System Design: Efficient cooling is essential for reducing cycle time and preventing defects. 3D CAD software can simulate the cooling process and help design an optimal cooling system within the mould.

Undercuts and Side Actions: Undercuts and side actions can be challenging in injection moulding. 3D CAD allows for the visualization and modification of these features to ensure they don’t hinder the moulding process.

Mould Flow Analysis: Advanced 3D CAD programs offer mould flow analysis tools that simulate the flow of plastic through the mould. This analysis can predict potential issues like air traps, weld lines, or short shots, enabling preemptive design adjustments.

Tolerance and Fit: Ensuring components fit together properly is vital. 3D CAD enables precise tolerance setting, ensuring parts assemble correctly after production.

Injection Moulding Tooling and Tools

Injection moulding tooling is an intricate and sophisticated process, central to the success of injection moulding operations. This process involves the creation and design of moulds that will be used to shape the molten material into final products. High-quality injection moulding tools are essential for ensuring the precision and longevity of these moulds. The development of these tools requires a deep understanding of material science, engineering principles, and the specific requirements of the injection moulding process. The design of the mould must consider factors such as the type of material to be used, the desired properties of the final product, and the complexities involved in the moulding process. This includes the design of the mould cavity, core, and the overall mould assembly. The precision in the design of these tools is crucial because even the slightest deviation can lead to product defects or inconsistencies. Therefore, investment in high-quality tooling is a critical decision for manufacturers, directly impacting the efficiency and quality of their production processes.

The creation of injection moulding tools incorporates advanced techniques and technologies to meet the demanding precision and durability requirements. The process typically begins with a detailed 3D model of the mould, developed using sophisticated computer-aided design (CAD) software. This model is essential for visualizing the final product and for planning the moulding process. The material selection for the mould is a vital factor, with options ranging from hardened steel for high-volume production to aluminum for shorter production runs or prototypes. Each material offers different benefits in terms of durability, heat resistance, and cost. The actual manufacturing of the mould involves precise machining processes, often using computer-aided manufacturing (CAM) technology. This ensures that every dimension and feature of the mould is produced with exacting accuracy. The tooling process also includes the creation of various components of the mould, such as gates, runners, and cooling systems, which are integral to the efficiency of the moulding process. The final stage involves rigorous testing and fine-tuning of the mould to ensure it meets all specifications and can produce parts with the required precision and quality. This level of attention and sophistication in injection moulding tooling underscores its significance in the manufacturing landscape, highlighting why it's considered a crucial investment for any manufacturer seeking to produce high-quality, precision parts.

Types and Products of Injection Moulding

Injection moulding's versatility is showcased by its ability to work with a variety of materials and machinery, leading to an extensive range of products. Each type of injection moulding has its unique characteristics and applications.

Plastic Injection Moulding

Plastic injection moulding is the most widespread method in the manufacturing industry, renowned for its efficiency in producing a broad spectrum of products. This process is pivotal in creating items for various sectors, ranging from children's toys and electronic housings to critical automotive components. The success of plastic injection moulding hinges on the intricacies of the underlying plastic design. A well-thought-out design is crucial not only for the functionality of the final product but also for its aesthetic appeal and durability.

The process involves a detailed focus on the injection mould design, which is geared toward ensuring a smooth flow of molten plastic into the mould. This design process is iterative and demands a deep understanding of plastic behavior, the specific functionality of the intended product, and the capabilities of the manufacturing machinery. When designing plastic parts for injection moulding, attention to detail is paramount. Designers must ensure that the moulding process is efficient, minimizes material wastage, and results in flawless parts. This specialization in design is a testament to the complexity and precision required in plastic injection moulding.

Blow Injection Moulding

Blow injection moulding is another key variant, primarily used for creating hollow objects like bottles and containers. This method combines the principles of injection moulding and blow moulding. Initially, a preform is created using injection moulding. This preform is then heated and placed in a blow mould, where it is inflated into the desired shape. This technique is particularly useful for manufacturing items that require a hollow interior and uniform wall thickness, making it a popular choice in the packaging industry.

Rubber Injection Moulding

Rubber injection moulding holds a special place in the manufacturing of flexible and durable rubber parts. This method is similar to plastic injection moulding but is specifically tailored for rubber materials. It is ideal for producing a wide range of rubber components, from automotive seals and gaskets to complex medical devices. The key to successful rubber injection moulding lies in the precise control of temperature and pressure, ensuring that the rubber cures properly within the mould to form high-quality parts.

Injection Moulding at Home

The advent of smaller, more affordable injection moulding machines and DIY moulds has opened the doors of this technology to hobbyists and small-scale creators. Injection moulding at home allows individuals to experiment with creating custom parts and prototypes in their own garages or workshops. This has been particularly beneficial for inventors, small businesses, and educators, providing them with the ability to bring their ideas to life without the need for large-scale industrial equipment.

Injection Moulding Costs

The cost of injection moulding is a critical consideration for businesses, varying widely based on design complexity, material choices, and production volume. Complex designs requiring sophisticated tooling or unique moulds tend to increase initial costs. Similarly, the selection of materials can significantly impact the budget, with specialized polymers costing more than standard options. However, once the injection moulding process is set up, the per-unit costs typically become more economical, especially for large production runs. This efficiency, driven by the high repeatability and rapid production capabilities of injection moulding machines, makes it an attractive option for mass production, offering significant cost advantages over other manufacturing methods.

For businesses with specific needs, custom injection moulding offers tailored solutions, allowing for a high degree of customization in design and materials. This approach is ideal for projects where standard solutions fall short or when differentiation is crucial. Many companies providing injection moulding services encompass a full spectrum of offerings, including design, prototyping, production, and post-processing. This comprehensive approach not only ensures high-quality output but also adds value by delivering a finished product that is market-ready, making custom injection moulding a versatile and cost-effective choice for a wide range of applications.

Whether you're exploring injection design for a new product line or aiming to refine an existing one, a solid grasp of plastic mould design principles can make all the difference. Remember, a well-designed mold not only ensures efficient production but also paves the way for high-quality products.

Integrating 3D CAD with Injection Moulding

In the modern era, integrating 3D CAD tools with injection moulding has never been more important. Whether you're looking to purchase an injection moulding machine for sale or exploring injection moulding design, a collaborative tool for 3D CAD files is invaluable. Such tools allow teams to collaborate seamlessly, reduce errors, and accelerate the time-to-market for products.

For those in the injection moulding industry or those considering it, investing in a reliable 3D CAD collaboration tool can be the difference between a good product and a great one. After all, precision, efficiency, and collaboration are the hallmarks of successful manufacturing.

If you're interested in a state-of-the-art collaborative tool for 3D CAD files, explore Jinolo. Perfectly suited for injection moulding professionals and other industries alike, our tool promises seamless collaboration, streamlined design processes, and much more! Sign up free today!